Essential Guide to the 92/96-fw Tension Wheel Feederwheel: Enhancing Plastic Strapping Efficiency

$85.00

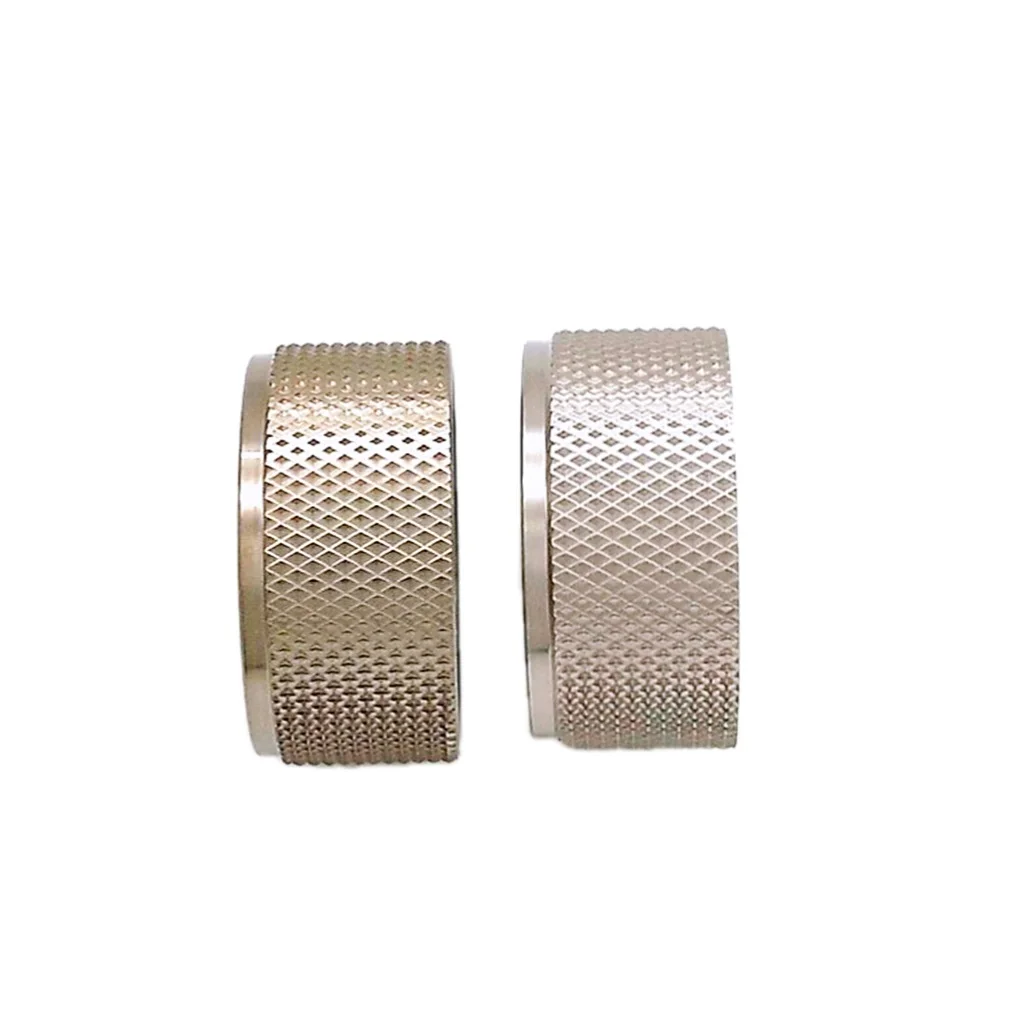

Introducing the 92/96-fw Tension Wheel Feederwheel, a game-changer for your Zp96 Battery-Operated Hand Tool. Enhance your plastic strapping efficiency, durability, and precision with our robust and reliable tension wheel that ensures smooth and consistent tensioning.

92/96-FW Tension Wheel Feederwheel: A Comprehensive Review for Professional Strapping Applications

Introduction

The 92/96-FW Tension Wheel Feederwheel is an essential accessory for the Zp96 Battery Operated Hand Tool, a versatile tool for strapping applications in various industries. This feederwheel plays a crucial role in ensuring proper tensioning and feeding of plastic strapping during the strapping process, resulting in secure and reliable packaging. This in-depth review will delve into the key features, benefits, and applications of the 92/96-FW Tension Wheel Feederwheel, providing insights into its effectiveness and value.

Key Features

-

Adjustable Tension: The tension wheel is equipped with an adjustable mechanism that allows users to fine-tune the tension applied to the strapping. This feature is crucial for securing different types of packages effectively, preventing damage or breakage.

-

Smooth Feeding: The feederwheel is designed to provide smooth and consistent feeding of the strapping, ensuring efficient and uninterrupted operation. This eliminates snags or interruptions during the strapping process, reducing downtime and increasing productivity.

-

Durable Construction: The 92/96-FW Tension Wheel Feederwheel is ساخته شده از materials that are resistant to wear and tear, ensuring long-lasting performance even in demanding industrial environments. Its robust construction withstands heavy use, making it a reliable investment for businesses.

-

Ergonomic Design: The feederwheel is designed with ergonomics in mind, featuring a comfortable grip that reduces operator fatigue during prolonged use. This ergonomic design enhances productivity and comfort, especially when working on large batch strapping operations.

Benefits

-

Enhanced Strapping Security: The adjustable tension mechanism ensures that the strapping is appropriately tensioned, providing a secure hold on packages. This prevents the strapping from becoming loose or breaking during transportation or storage, ensuring product integrity.

-

Increased Efficiency: The smooth feeding operation eliminates snags or interruptions, allowing for continuous and efficient strapping. This reduces downtime, increases productivity, and streamlines the packaging process.

-

Reduced Material Waste: By feeding the strapping smoothly and evenly, the 92/96-FW Tension Wheel Feederwheel minimizes material waste. It ensures that the strapping is used optimally, reducing costs and promoting sustainability.

-

Improved Operator Comfort: The ergonomic design provides a comfortable grip, reducing fatigue and discomfort during extended use. This improves operator well-being and enhances productivity by reducing the risk of strain or injury.

Applications

The 92/96-FW Tension Wheel Feederwheel is widely used in various industries for strapping applications, including:

-

Packaging and Shipping: The feederwheel is ideal for securing boxes, crates, and other packages during shipping, ensuring safe and secure transportation.

-

Manufacturing: It is used in manufacturing processes to bundle materials, components, and finished goods for efficient storage and handling.

-

Agriculture: The feederwheel is employed in agricultural settings to secure bales of hay, straw, or other agricultural products for transportation and storage.

-

Construction: It is used in construction projects to secure materials such as lumber, pipes, or equipment for safe and secure transportation or storage.

Conclusion

The 92/96-FW Tension Wheel Feederwheel is an essential accessory that enhances the performance of the Zp96 Battery Operated Hand Tool. Its adjustable tension, smooth feeding, durable construction, and ergonomic design make it a valuable tool for professional strapping applications in various industries. By ensuring proper tensioning and feeding of plastic strapping, the feederwheel contributes to secure and reliable packaging, while also increasing efficiency, reducing material waste, and enhancing operator comfort. Investing in the 92/96-FW Tension Wheel Feederwheel is a wise choice for businesses and professionals seeking to optimize their strapping operations and achieve superior results.